The common question we often encounter is, “What distinguishes HVO fuel from high-blend biodiesel, and how do they differ?” HVO Fuel, standing for Hydrotreated Vegetable Oil, is gaining prominence, and rightfully so, as one of the popular choices for renewable fuel.

Both High Blend Fuel and HVO play integral roles in the renewable energy mix and the ongoing energy transition, both are also categorised as biofuels. In this article, we aim to provide a comprehensive overview of the key differentiators between the two, helping you have a clearer understanding in determining the most suitable option for your current needs. This information proves particularly valuable if you are currently in the process of evaluating renewable fuel options for your fleet and are exploring the various alternatives available.

What They Are?

What is HVO Fuel?

What is HVO Fuel?

HVO means Hydrotreated Vegetable Oil, it’s a type of biofuel that is made through the hydroprocessing of renewable feedstocks like vegetable oils or animal fats. The composition of HVO closely resembles fossil diesel however it offers significantly reduced greenhouse gas emissions given its properties.

What is Biodiesel?

What is Biodiesel?

Biodiesel, a form of biofuel, is derived from sources such as used cooking oil, food waste, and animal fats. Similar to HVO, the utilisation of specific raw materials in its production results in a sustainable second-generation fuel, offering a sustainable alternative to traditional fossil fuels. Biodiesel can be directly blended with fossil fuel diesel and currently, the standard pump (retail) diesel on the road is a B7 blend, which contains up to 7% biodiesel, with the remainder being fossil fuel diesel. Blends that exceed 10% biodiesel content are categorised as ‘High Blend Fuel’ or ‘High Blend Biodiesel’. The higher the percentage of biodiesel in the blend, the greater the reduction in CO₂ emissions. So, essentially, a High Blend Fuel is a mixture of two distinct fuels: biodiesel and fossil fuel diesel.

Sustainability and Environmental Benefits

Sustainability and Environmental Benefits

The use of biodiesel decreases the impact of global warming, enables energy independence, and supports agriculture. Sourcing biodiesel or HVO instead of fossil fuels, allows for the active avoidance of new GHG emissions to the atmosphere. Being renewable means these two biofuels do not add to the amount of carbon being recycled through the atmosphere, which means it does not increase the net amount of greenhouse gases (GHGs) affecting climate change. This is because the production of feedstock used in both manufacturing processes naturally absorbs carbon from the atmosphere, thereby acting as a carbon emissions offset for emissions produced via the tailpipe of the transport vehicle.

On a local level, HVO and biodiesel have numerous environmental benefits, both contributing to a reduction in air pollutants when compared to traditional fossil fuels. These biofuels result in improved air quality as they emit lower levels of particulate matter, sulphur dioxide, and a reduction in carbon monoxide emissions.

The feedstocks used in the production of these two fuels promote sustainable practices and reduce the environmental impact associated with conventional fuel production. Unlike fossil fuels, which release carbon dioxide stored for millions of years, biofuels like HVO and biodiesel are considered carbon-neutral over their lifecycle, making them an environmentally friendly fuel alternative.

Greenhouse Gas Savings

Comparing Environmental Impact: HVO vs. Biodiesel Blends

The Well-to-Wheel (WTW) Greenhouse Gas (GHG) Emission Savings for each is dependent on the type of feedstock used and the manufacturing process itself. If HVO is manufactured in a certain way, and if genuine certified waste materials are used for both biofuels, typical GHG emissions can be seen below.

| Fuel Solutions | GHG Savings |

|---|---|

| HVO (Hydrotreated Vegetable Oil) | 81-91% reduction in Well-to-Wheel (WTW) Greenhouse Gas (GHG) Emission Savings* |

| Argent Biodiesel (B100) | 83% reduction in Well-to-Wheel (WTW) Greenhouse Gas (GHG) Emission Savings. |

| B30 (30% biodiesel blended with fossil fuel diesel) | 26% reduction in Well-to-Wheel (WTW) Greenhouse Gas (GHG) Emission Savings |

| B20 (20% biodiesel) | 18% reduction in Well-to-Wheel (WTW) Greenhouse Gas (GHG) Emission Savings |

| B15 (15% biodiesel) | 14% reduction in Well-to-Wheel (WTW) Greenhouse Gas (GHG) Emission Savings |

| B10 (10% biodiesel) | 10% reduction in Well-to-Wheel (WTW) Greenhouse Gas (GHG) Emission Savings |

Renewable Fuels: Well-to-Wheel GHG Emissions Comparison

When opting for a blend of biodiesel with fossil fuel diesel, the flexibility to customise the mixture arises, allowing you to select the best blend ratio based on various factors. For example, a High Blend Fuel with a composition of B30 (30% biodiesel, 80% fossil fuel) can achieve around a 26% reduction in your fleet’s CO₂ emissions.

Download Biodiesel Specifications

Click here to view the technical specifications of High Blend Biodiesel.

Engine Performance and Cold Weather Performance

Both HVO and High Blend Biodiesel exhibit levels on par with traditional diesel, minimising compromise. HVO is known for its alikeness to conventional diesel, this similarity extends to key aspects such as power output, efficiency, and overall reliability.

High Blend Fuel, with its increased biodiesel blend, maintains performance similar to traditional diesel, featuring a higher cetane rating for improved ignition and combustion efficiency. The inherent lubricating properties of biodiesel in High Blend Fuel additionally contribute to reduced engine friction.

In cold weather, both HVO (Hydrotreated Vegetable Oil) and high blend biodiesel exhibit reliable performance. HVO proves its compatibility with low temperatures, ensuring seamless operation akin to traditional diesel. High Blend Biodiesel, with its enhanced cetane rating, maintains ignition ease and efficiency, making it well-suited for cold climates.

HVO and High Blend Compatibility

Compatibility of HVO and High Blend Biodiesel with Existing Infrastructure

The compatibility of HVO and High Blend Biodiesel with existing infrastructure is a pivotal aspect when evaluating their viability as renewable fuel options. HVO, being chemically similar to fossil diesel, exhibits a high level of compatibility with existing diesel infrastructure. Its integration into conventional diesel engines and fuelling infrastructure minimises the need for extensive modifications, making it a convenient and practical choice for transition.

High Blend Biodiesel exhibits compatibility, contingent upon the selected blend rate. Blends up to B30, containing 30% biodiesel, preserve compatibility with existing diesel infrastructure, often recognised for their seamless integration and referred to as a ‘drop-in replacement solution.’ High Blend Biodiesel, up to B30, is warrantied by most manufacturers, adding a layer of assurance to its usage. Any High Blend Biodiesel suppliers approved by the Renewable Fuels Assurance Scheme (RFAS), will have the capability to manage and advise on infrastructure compatibility.

Click here for a guide of heavy-duty vehicle manufacturers’ warranty positions for different biodiesel blends and HVO, as identified by the Zemo Partnership.

Biofuel Cost Comparison

Biofuel Cost Comparison of HVO Fuel and High Blend Fuel:

Cost is undeniably a major consideration in a fleet’s decision-making process. HVO bears a premium in the market, with the HVO fuel price per litre ranging between 15% and 30% higher than traditional diesel according to Zemo’s Renewable Fuels Guide.

In contrast, High Blend Biodiesel emerges as a cost-effective alternative, often incurring little to no additional expense compared to standard diesel rates. Depending on the supply chain, High Blend Biodiesel can even offer fuel cost parity with fossil fuel.

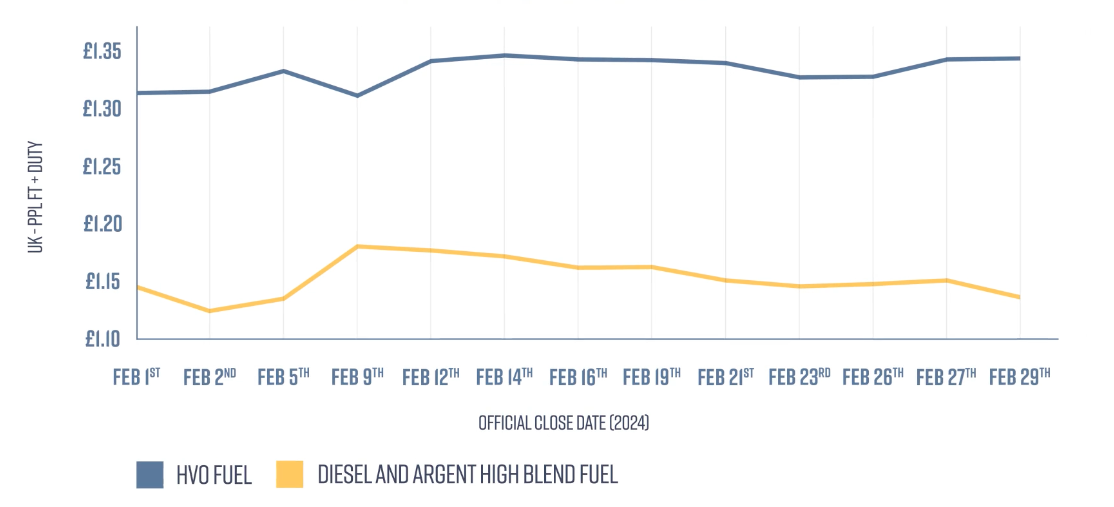

While costs are subject to variation based on several factors, an illustration can be seen below comparing the typical fuel prices per litre in the UK for each. The data used is from February 2024.

Availability and Distribution

While HVO offers commendable attributes and significant greenhouse gas (GHG) emission savings, there can be logistical challenges due to limited refueling stations. The United Kingdom also does not produce HVO domestically. Instead, the country relies on importing HVO from various sources, including Europe and Asia where crops are frequently used for production. Despite these considerations, adopting HVO remains a viable step towards sustainability, offering notable environmental benefits that operators can leverage with careful planning and integration. HVO distribution has risen sharply in recent years with a number of major international organisations using it as part of their decarbonisation goals.

High Blend Biodiesel is readily available from a number of suppliers across the UK, and is produced from both UK and international markets. All biodiesel made in the UK is produced using only certified waste, with no crops used. According to Zemo, B20 and B30 blends have experienced the greatest market penetration, with B20 being deployed in several thousand buses over the last decade, estimating approximately 2,000 buses and 1,500 HGVs across the UK are running on high blend biodiesel. Blends such as B20 or B30 can seamlessly integrate into existing infrastructure with minimal modifications, providing fleet operators with a practical choice to reduce environmental impact and maintain operational cost-effectiveness.

HVO and High Blend Fuel Video

HVO and High Blend Fuel Video

YOUR DECISION

For fleet operators evaluating renewable fuel options, the decision between HVO, biodiesel and High Blend Biodiesel involves striking a balance between environmental benefits, practical considerations, and price. HVO stands out as a fuel for achieving significant GHG emission reductions and as an immediate solution for fleet operators looking to use a renewable fuel with no extensive need to change infrastructure, albeit at a cost. Biodiesel (B100) offers high GHG emission reduction, but fleet operators wanting to use B100 for their fleet will require engine modification. On the other hand, High Blend Fuel (biodiesel blends) proves to be a cost-effective choice for fleets seeking decarbonisation without incurring any additional expenses.

If you’re looking to start your sustainable journey, always make sure to use companies recognised as Renewable Fuel Suppliers as approved under the Renewable Fuels Assurance Scheme (RFAS), an initiative designed and managed by the Zemo Partnership.

Enquire about High-Blend Biodiesel

Are you interested in High Blend Biodiesel?

Argent Fuels has been a supplier of carbon-saving fuel to the long-haul trucking industry since 2008, supplying the likes of Metroline and Stewart Hymas with B20 and B30 blends. Get in touch today for a free consultation.