Argent’s waste-based biodiesel is a distilled product that can be directly blended with conventional diesel and used as a fuel, typically in trucks, buses, vans and cars. In this way it contributes proportionately to the lowering of CO2 emissions of the vehicles it powers

Our Process

The Steps

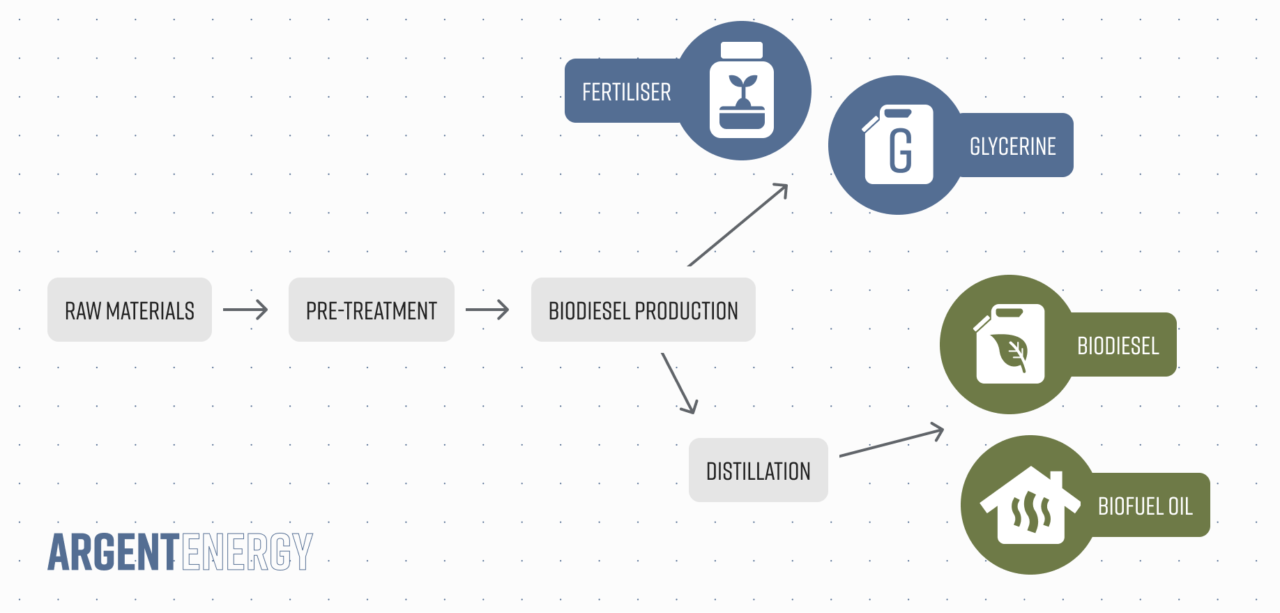

Pre-treatment

The severely degraded fats & oils are processed to remove impurities in order to enhance biodiesel yield, decrease in-line process and maintenance issues as well as decrease overall chemical usage.

Biodiesel production – Step 1

Any free fatty acid present in the oil is reduced to a manageable level limiting issues further down the process. Argent’s capability to do this is one of the main reasons why we can handle severely degraded oils such as FOG and grease trap waste.

Biodiesel production – Step 2

The oil is reacted again, under different conditions, and at this stage the vast majority of the biodiesel is synthesised. Any oil that is not converted at this stage is collected and put back into the process, ensuring a high conversion to biodiesel.

Side product creation

The discharges from the previous two steps are collected and then reacted together; yielding our fertiliser and glycerine side products.

Distillation

Post-reaction the crude biodiesel is put through a distillation column as a final polish to ensure Argent Energy produces biodiesel of a consistent high quality. At the distillation step, biofuel oil is also collected as a by-product which is used as marine fuel making sure that very little waste is produced overall during the process.

Completion

The biodiesel undergoes comprehensive testing and analysis, and is then ready to go.

Industries and Applications

Industries and Applications

We produce fuels which have many varied applications, and the list is growing longer. Find out more about how we collaborate to reduce the carbon footprint of many industry sectors.